TECHNOORG LINDA

SEMPrep SMART

SEMPrep SMART는 고에너지 및 선택적으로 저 에너지 Ar 이온 소스를 갖추고 있습니다.

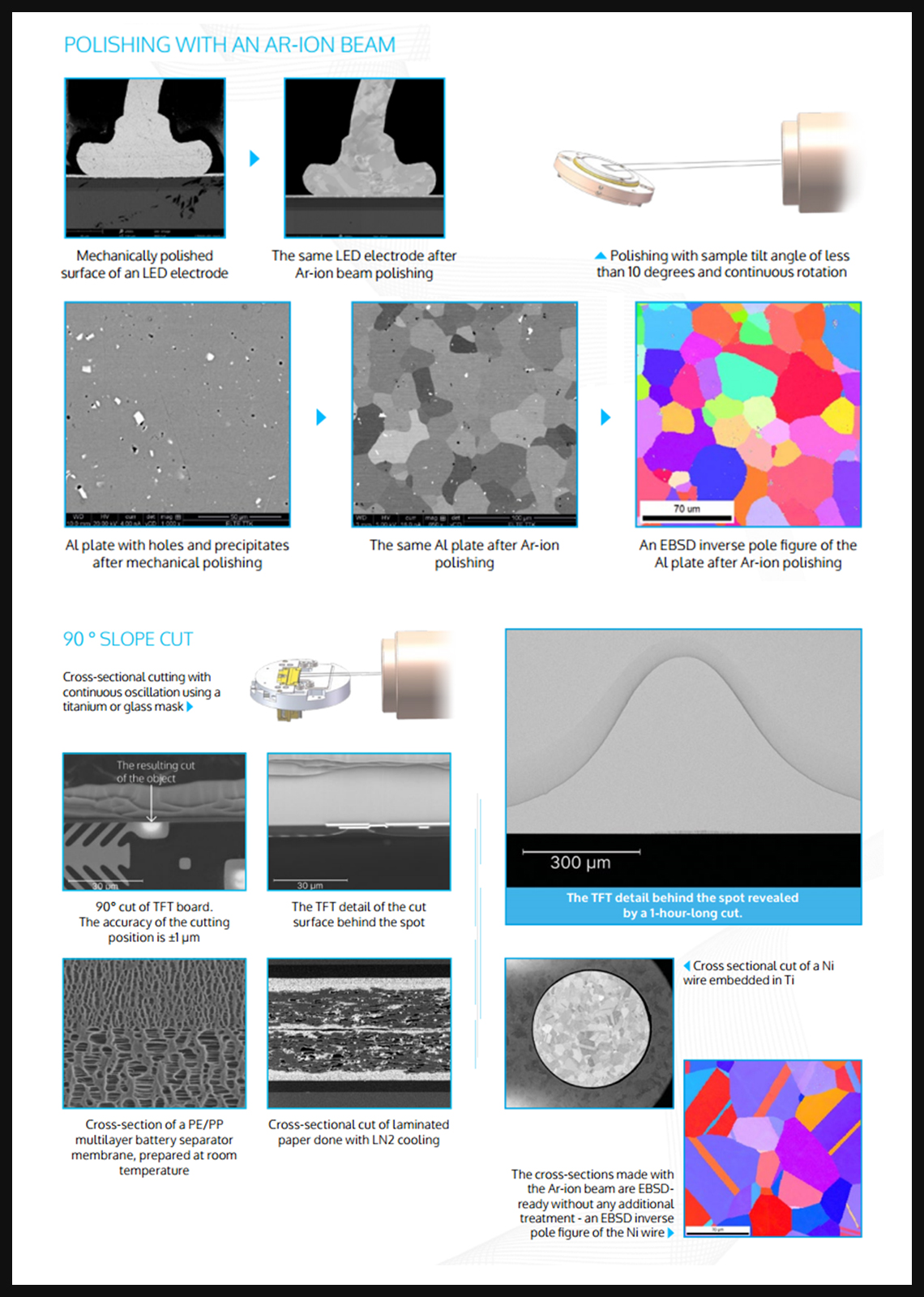

LINDA CP는 전통적인 SEM 및 EBSD 샘플의 최종 연마 및 세척에 이상적인 선택입니다. 이온 연마는 기계적으로 연마된 SEM 샘플을 개선하고 세척하고 EBSD 분석을 위해 손상 없는 표면을 준비할 수 있습니다.

반도체 테스트, 리튬이온배터리 분리막 멤브레인의 단면 조사와 같이 높은 정밀도와 품질이 필요한 경우에도 뛰어난 결과가 가능합니다.

경사면 스퍼터링 기능과 함께 표면의 Sample Damage를 줄이기 위해 저전압 후처리 기능 또한 제공가능합니다.

단면 식각이 필요한 SEM, EBSD 유저에게 특화되어 있습니다.

SEMPREP SMART features

- Low-energy Gun(LEG) 옵션

- LN2 또는 Peltier 시료 냉각 시스템

- 진공 내에서 시료 이동을 위한 진공 이송 장치(Vacuum Transfer Unit) 옵션

- 정밀한 위치 조정을 위한 독립형 시료 조정 시테이션

Easy to Use Solutions

- 문제 및 오류 감지 시스템

- 대면적 자동화 기능

- 최첨단 제어 소프트웨어

- 인터넷 연결을 통한 원격 제어 및 모니터링

Quality and High Precision

- 고정밀 빔 조정

- 세밀한 가공을 위한 정밀 조정 기능

- 작동 중 샘플 관찰을 위한 고해상도 디지털 카메라

Advanced Technologies

- 현존하거나 개발중인 모든 기기를 지원

- 가스 흐름을 미세하게 조정할 수 있는 고정밀 니들 밸브

- 긴 수명의 고진공 센서

SEMPrep SMART

| Models & Specification | ||||

|---|---|---|---|---|

| Items |  |

|

|

|

| Model | SEMPrep SMART | SEMPrep2 | GentleMill | |

| Ion Sources |

Two ion gun |

- High-energy ion gun operating up to 10 keV or ultra-high-energy ion gun operating up to 12 keV (Optional) - Low-energy ion gun in the range of 100 eV to 2 keV continuously and independently adjustable milling energy |

- High-energy ion gun operating up to 10 keV or ultra-high-energy ion gun operating up to 16 keV (optional) - Low-energy ion gun in the range of 100 eV to 2 keV continuously and independently adjustable milling energy |

Low-energy ion gun in the range of 100 eV to 2 keV continuously and independently adjustable milling energy |

| Sample Stage |

Sample size |

Slope cutting sample holder (available with 30˚ and 90˚ tilted platforms) for 30˚ holder : max. 16.4 mm (l) × 16 mm (w) × 3.1 mm (th) for 90˚ holder : max. 18.6 mm (l) × 16 mm (w) × 6 mm (th) sample holder for surface cleaning using 3 different head types : flat head type : max. Ø50 mm × 4 mm standard type : max. Ø32 mm × 15 mm hollow type : max. Ø25 mm × 23 mm |

Slope cutting sample holder (available with 30˚ and 90˚ tilted platforms) for 30˚ holder : max. 42 mm (l) × 16 mm (w) × 5.5 mm (th) for 90˚ holder : max. 20 mm (l) × 16 mm (w) × 7.0 mm (th) sample holder for surface cleaning using 3 different head types : flat head type : max. Ø33.5 mm × 8 mm standard type : max. Ø33.5 mm × 9 mm hollow type 1 : max. Ø26 mm × 21 mm hollow type 2 : max. Ø32 mm × 19.5 mm |

Depend on TEM Grid : 3.05 mm |

| Sample tilting |

0˚ to 30˚ in 0.1˚ increments | 0˚ to 30˚ in 0.1˚ increments | - | |

| Sample rotation |

in-plane rotation, 360˚ | in-plane rotation, 360˚ | - | |

| Sample oscillation |

in-plane oscillation from ±10˚ to ±120˚ in 5˚ steps |

in-plane oscillation from ±10˚ to ±120˚ in 5˚ steps |

- Milling angle : 0˚ - 40˚, electronically adjustable in 0.1˚ increments - Computer controlled in-plane specimen rotation and oscillation (from ±10˚ to ±120˚, electronically adjustable in 10˚ steps) - Remarkable thickness range of the accepted TEM sample (maximum 200 μm) |

|

| Sample Cooling |

LN2 cooling to prepare heat-sensitive samples (optional) | LN2 cooling to prepare heat-sensitive samples (optional) | - | |

| Vacuum System |

Oil-free diaphragm and turbomolecular pumps with combined (Pirani / Penning) vacuum gauge | Oil-free diaphragm and turbomolecular pumps with combined (Pirani / Penning) vacuum gauge | Oil-free diaphragm and turbomolecular pumps with combined (Pirani / Penning) vacuum gauge | |

| Gas Supply System |

- 99.999% purity argon - Dry nitrogen venting option - Electronic working and venting gas pressure monitoring - High-precision working gas flow control |

- 99.999% purity argon - Dry nitrogen venting option - Electronic working and venting gas pressure monitoring - High-precision working gas flow control |

- 99.999% purity argon - Dry nitrogen venting option - Electronic working and venting gas pressure monitoring - High-precision working gas flow control |

|

| Imaging System |

High-resolution CMOS camera with fix zoom | High-resolution CMOS camera with fix zoom | - High-resolution color CMOS camera - Manual zoom video lens of 50 - 400× magnification range |

|

| Computer Control |

Easy-to-use graphical interface, automated ion source setup, milling parameter setting and operation control | Easy-to-use graphical interface, automated ion source setup, milling parameter setting and operation control |

- Easy-to-use graphical interface and image analysis module - Automatic termination : optical termination of the milling process supported by an image analysis module (detecting the sample perforation or monitoring the surface topography) |

|