A study of the coated area of Alloy metal using automated SEM-EDS anal…

페이지 정보

본문

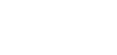

▪ The international standard ASTM recommends about 10 micron alloy coating. As the last surface treatment process in the root industry, it is an indispensable process, and coating treatment plays an important role in overcoming the physical, chemical, and emotional limitations that a product can realize. However, in order to observe the coating state of these mass-produced materials of various scales, research has generally

been conducted with portable XRF or SEM-EDS, but in this case, only a local area of the material can be observed, and portable XRF has limitations in quantitative analysis.

▪ If only local areas are observed, it is difficult to determine the exact quality of mass-produced materials. To compensate for this limitation, an electron microscope (ThermoFisherScientific : Axia ChemiSEM) suitable

for automatic large-area analysis was used, and at the same time, large area mapping was performed to observe the coating state over a large area.

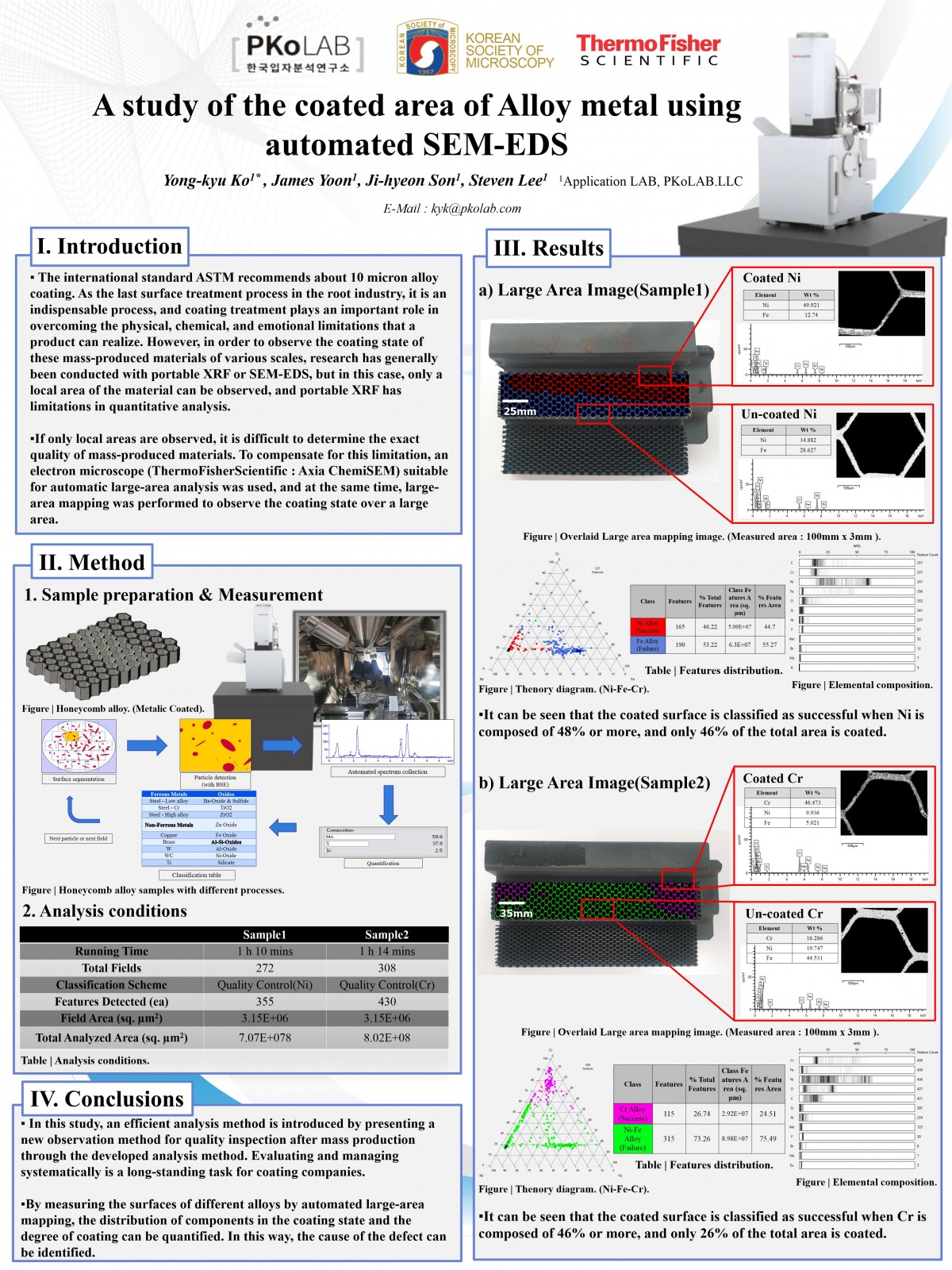

▪ In this study, an efficient analysis method is introduced by presenting a new observation method for quality inspection after mass production through the developed analysis method. Evaluating and managing systematically is a long-standing task for coating companies.

▪ By measuring the surfaces of different alloys by automated large-area mapping, the distribution of components in the coating state and the degree of coating can be quantified. In this way, the cause of the defect can be identified.